Solar Materials

Encapsulant

Encapsulant of  has

has

excellent quality with Calender and T-Die method.

Product Info.

-

Facility to Supply Products

according to Customer Needs Calendering

& T-Die -

World-class

Productivity -

Various Products Line Up

High-functional

Product Family

It is a sheet which is used for adhesion of Glass/Cell/Backsheet of solar cell modules and for cell protection (encapsulant), and which requires long-term durability (more than 25 years) and optical characteristics. Hanwha Advanced Materials supply high quality raw materials based on Hanwha Group's global competitiveness in the EVA raw material market for solar cells. Our EVA sheets have been recognized for its superior quality all over the world by applying the highly-regarded calendar process and T-die method.

Application

Type

HEP Series

Fast Cure-

Properties Unit Data Test Method & Remarks Degree of Cross-linking % ≥80 Lamination(@150°C, 15min) Adhesion to Glass N/cm ≥100 Hanwha Method Shrink Rate % ≤3 120°C, 5min

- Ultra Fast

Cure -

Increases module productivity by reducing lamination time

Performance

- Reduces Lamination time

Total time :

Temp. Vacuum Press 150 4~5 7~8 160 5~6 165 4~5

-

Speed of Cross-linking at 150°C Lamination

-

Speed of Cross-linking at 160°C Lamination

- Reduces Lamination time

- UV Through

-

Increased solar module efficiency achieved through optimal UV range transmittance

Performance

- Increase of 2~3 Wp (with Multi Cell)

- Increase of 3~5 Wp (with Mono Cell)

UV-T Module Use of UV AB range

- Increase in module efficiency

- Secure light resistance from UV range

UV Range Transmittance

HEP Series (Anti-Hydrolysis)

Anti-Hydrolysis

Anti-Hydrolysis

- Minimizes hydrolysis of polymer chains in EVA, maintaining the output of TOPCon cell modules under high temperature/humidity environment.

- DH 2000hr (M10 TopCon cell / G2F type)

| Initial | 1000hr | 2000hr | △Pmax | |

|---|---|---|---|---|

| TopCon EVA |  |

|

|

- 0.7% |

| HAMC POE |  |

|

|

- 0.7% |

| Competitor-1 EPE |  |

|

|

- 0.8% |

| Competitor-1 POE |  |

|

|

- 0.7% |

| Competitor-2 EPE |  |

|

|

- 0.1% |

| Competitor-2 POE |  |

|

|

- 1.1% |

HPO Series

POE Sheets produced by Hanwha Advanced Materials provide excellent moisture resistance, great

Anti-PID ability and offer superior protection against metallic corrosion in Bus/finger bar caused by Acetic acid.

- Feature

-

- High Transmittance, reliability and Adhesion Power.

- Lower water transmittance compared to EVA Sheet.

- Prevents cell damage from current leakage in modules.

- WVTR

-

WVTR EVA ≤ 30 POE ≤ 10

- Structure

PID Test -

※ PID 85℃, 85%RH, 1000V (P-type mono-facial / G2F type)

Technical Data

- Physical Properties of EVA Sheetdownload

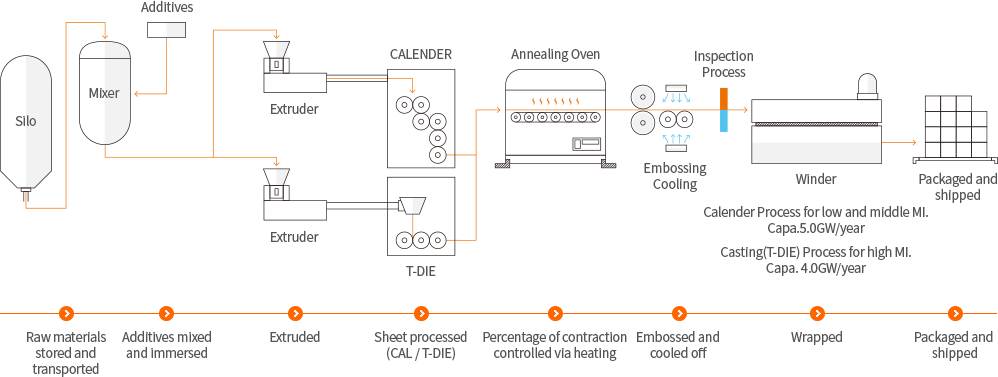

Production Process

Material Process

Inquiries

Solar Materials

- kis8park@hanwha.com