SHE Management

Management coexisting with the environment

We create a zero-harm, eco-friendly workplace based on strict company guidelines and preventive systems.

Environment, health, and safety management policy

To achieve sustainable corporate development and fulfill social responsibilities, acknowledges environment, health, and safety as n inherent values of

acknowledges environment, health, and safety as n inherent values of

corporate management and makes the following efforts.

-

01 Environment, Health, and Safety

prioritized management We eliminate risk factors and minimize risks considering environment,

health, and safety as the top priority goals of management. -

02 Creating safe work environment

We strive to create a safety culture and a safe work environment that involves

all executives and employees. -

03 Complying with environment and

safety regulations We voluntarily comply with rules and regulations and seek continuous

activities for improvement. -

04 Responding to climate change

We contribute towards the conservation of the global environment by

minimizing pollutant emissions and reducing greenhouse gases.

CEO In-Hwan Kim

Safety/health management

- Structured system operation

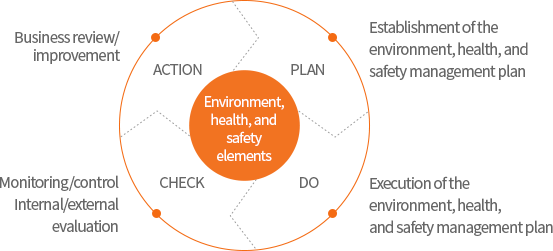

- Based on the PDCA Cycle required by the occupational health and safety management system (ISO 45001), we systematically implement the system and practice health and safety management through constant improvement, while also carrying out activities to handle the risk factors in the processes that may lead to severe industrial accidents such as fire, explosion, and leakage.

Environment, health, and safety elements

- PLAN

- Establishment of the environment, health, and safety management plan

- DO

- Execution of the environment, health, and safety management plan

- CHECK

- Monitoring/control

Internal/external evaluation - ACTION

- Business review/improvement

- Participatory safety culture

- We strive to promote safety communication by regularly conducting safety inspections and safety meetings that are led by the management and involve both labor and management. Furthermore, by continuously finding and eliminating risk factors on-site, all employees are participating in creating a safe workplace.

- Safety risk management

- We are constantly finding potential harmful risk factors through risk assessments and minimizing risks by establishing improvement measures. Moreover, we strive to voluntarily comply with laws and regulations by regularly evaluating and inspecting compliance with health and safety rules.

- Promotion of employee health

- Healthcare programs are implemented so that not only all employees but also all of their family members can live a healthy and safe life.

Employee healthcare programs

- Management of cerebrovascular and cardiovascular diseases, and basic illnesses

- Stretching, smoking cessation, and sobriety programs

Actions on Climate change

Towards achieving carbon neutrality

has established mid- to long-term greenhouse gas reduction goals

has established mid- to long-term greenhouse gas reduction goals

and is conducting relevant activities to achieve carbon neutrality by 2050.

-

Creating multi-step

roadmap -

Purchasing

renewable energy -

Establishing an

eco-friendly

infrastructure -

Promoting greenhouse

gas/energy reduction

activities in each

business site

- Creating multi-step

roadmap - Creating a roadmap to reduce greenhouse gas emissions for each period (short-term, mid-term, long-term) by adopting reuse technology and high-efficiency facilities

- Purchasing

renewable energy - Achieving carbon neutrality by purchasing REC (Renewable Energy Certificate)

- Establishing an

eco-friendly infrastructure - Expanding an eco-friendly infrastructure by establishing energy-efficient facilities, using energy storage systems (ESS), adopting high-efficiency facilities, and adopting green vehicles

Environmental impact management

Environmental management systems and structures

- Air quality management

- We have established a policy to minimize air pollutants discharged from our business sites and are managing cumulative pollutant emissions by digitizing the data. We regularly monitor emissions by setting internal management standards that are stricter than the legal emission standards, and carry out activities to reduce pollutant emissions by preventing and blocking risk factors and improving pollutant prevention facilities.

- Water quality management

- We are managing cumulative emissions data by monitoring and analyzing wastewater in each process on yearly basis. In particular, we installed CCTVs for real-time management at the dewatering outlets for wastewater and rainwater generated on-site so that harmful substances are not discharged. Wastewater is treated internally and then ultimately treated at a public wastewater treatment facility in the industrial complex, thereby maintaining river water quality and the ecosystem and promoting environmental conservation.

- Waste

management - We consistently report on performance in relation to waste laws, policies, and systems, and we are transparently managing and disclosing the entire process of waste discharge, transport, and final disposal in real-time. We are also striving to increase the rate of waste recycling in our business sites by constantly discovering companies that can recycle waste.

- Chemical management

-

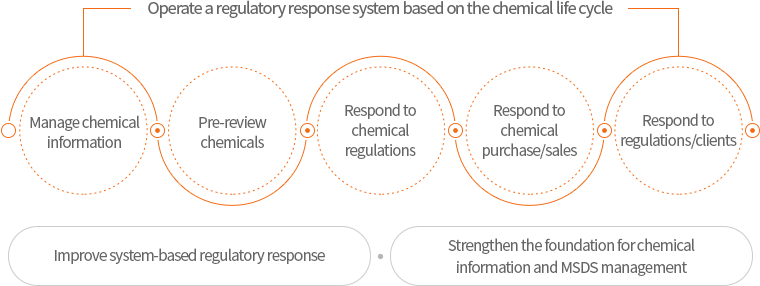

Improving the chemical management system

We have created a database of information on all chemicals handled at each business site through the corporate chemical management system (CMS) to improve system-based regulatory response and established an advanced system for chemical information management.

Chemical management process

Operate a regulatory response system based on the chemical life cycle

Operate a regulatory response system based on the chemical life cycle- Manage chemical information

- Pre-review chemicals

- Respond to chemical regulations

- Respond to chemical purchase/sales

- Respond to regulations/clients

- Improve system-based regulatory response

- Strengthen the foundation for chemical information and MSDS management

Cumulative management of chemicals using the DT system

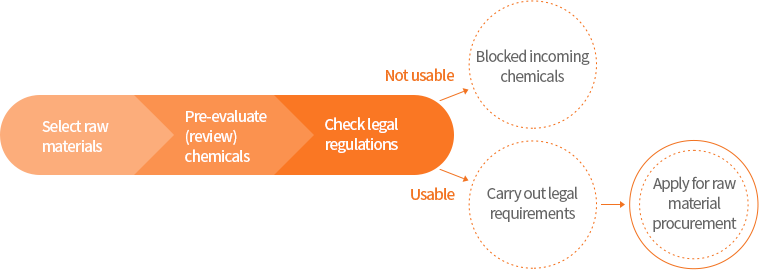

Implementation of a system that blocks incoming chemicals

- Select raw materials

- Pre-evaluate (review) chemicals

- Check legal regulations

- Not usable

- Blocked incoming chemicals

- Usable

- Carry out legal requirements

- Apply for raw material procurement

Environment/Safety/Health Policy

recognizes the value of corporate management of the environment, safety and in order to achieve sustainable corporate development and fulfill its social responsibilities, as revealed in the following:

recognizes the value of corporate management of the environment, safety and in order to achieve sustainable corporate development and fulfill its social responsibilities, as revealed in the following:

- 1 We put our best effort in delivering our products and services to satisfy our customers' expectations and demands while providing safe and environment-friendly products and services.

- 2 We ensure the safety and health of our employees and the general society by preventing human injury and property damage at all stages, from product development, manufacturing, sales to service delivery.

- 3 We establish and operate an environmental management system in order to preserve the environment and create a positive working environment, and conduct pollution prevention and continuous improvement activities at all stages of corporate management.

- 4 We are committed to efficiently utilizing and reducing resources and energy with a central control process throughout the entire course of our operations.

Environment and Safety Guidelines

Compliance with Legal Standards

In addition to fully complying with the relevant local and national government laws and the environment, health and safety regulations, we have established and adhered to stricter in-house standards that support proactive efforts in corporate social responsibility by complying with the various international regulations.

Establishment of a Line Liability System

We strictly follow environment, health and safety regulations. The primary responsibility lies with the individual, and the management responsibility lies with line management. Thus, the specific roles and responsibilities within the organization and its operating systems must be directly reflected in the performance of the organization and individual and measured with objective evaluation standards.

Establishment of an Emergency Response System

We have established clearly defined procedures clearly in preparation for possible emergencies and environment, health and safety related accidents. Through continuous and regular emergency drills, we minimize the impact of emergencies, and we actively cooperate with local communities to create a positive and safe community.

Establishment of an Environment Management System

Moving away from straightforward solutions such as simple financial duties and regulatory responses regarding environmental protection, we have established an environment management system that takes into account the environmental aspects of corporate management by establishing and implementing systematic and effective audit procedures.

Production of Environment-Friendly Products and Service

We review in advance the environmental impact of all business activities, including development, design, purchasing, production, sales, use, and disposal, in order to provide environment-friendly products and services that considers its environmental impact and countermeasures to protect the environment.

Global Environment Preservation and Pollution Prevention

We minimize the emission of environmental pollutants through reduction and effective treatment of pollutants generated for the entire duration of our operations.

Resource and Energy Source Management

We evaluate the appropriateness of all the material resources that are potentially used in our operations and strive to save energy efficiently through recollecting, reusing, and recycling.

Accident and Loss Prevention

Fatalities and property loss must be reported regardless of size, and the analysis of cause and preventative measures must be implemented. We thoroughly manage and prevent, in advance, the potential risks of serious accidents.

Reinforcement of Preventive Safety Measures

All risk factors in the workplace must be identified and assessed through regular inspections and related prior training, and efforts must be made to eliminate human and material damage by eliminating the risk factors or reinforcing safety facilities.

Supplier(Contractors) Safety Level

We maintain a mutually supportive relationship with our contractors and suppliers for the improvement of safety to our standard by providing our safety management system through guidance and support. For this, we establish a safety management system for suppliers and contractors that can be operated appropriately and effectively according to the type of industry and scale.

Ensuring the Safety of Products and Services

We establish a system that can secure the safety and health of our customers and local communities that use our products and services, and strive to improve safety with continuous research and development.

Maintaining a Positive Work Environment

We implement continuous improvement and systematic health management for workers in order to create a healthy and efficient working environment.

Prevention of Occupational Diseases

A practical management system must be established to prevent work-related diseases from occurring, and employees must actively participate. In case of occupational accidents or diseases, the work of the employee must be adjusted and coordinated reasonably.

Enforcement of a Health Promotion Program

A systematic program that includes pre- and post-management must be delivered for the promotion of employee health and for the prevention of the workforce turnover.