Automotive Materials

IntermLite

Interior Material, PMC (Powder Slush Molding Compound)

IntermLite is the brand name of PMC and internal materials of  .

.

Product Info.

- Excellent DesignEco-friendly Product

- Domestic PSM MarketM/S No.1

- Auto Interior Material Global Leader

IntermLite is the brand name of PMC products and interior materials of  .

.

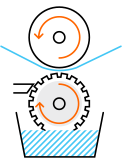

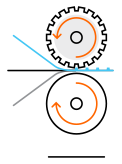

Interior materials are mainly used as automobile interior materials, and manufacturing processes of interior materials can be divided into three processes: calendar process, surface treatment process and plywood process. In the calendaring process, the raw material is mixed and melted, the thickness is adjusted, and then cooling and winding are performed. In the surface treatment process, the treating agent is transferred to the surface, followed by drying in hot air to go through a winding process. In the plywood process, the rolled sheet is unwound, heated, and then cooled again to wind. We are also diversifying into high-quality sheet-form materials to satisfy modern requirements for contemporary car designs, and environmentally friendly Thermoplastic Polyolefin and Thermoplastic Polyurethane for intricate designs.

PMC stands for Powder Slush Molding Compound. It has excellent moldability and low cost. PMC is a type of leather inside the vehicle, and the material of the powder is made into a skin type product by the rotation of the heated mold. It is mainly used as a skin material for automobile interior materials and has the merit of being able to realize complex shapes and excellent tactile sensitivity compared to other materials.

Features

- Excellent Durability/Light Resistance

- Excellent Degree of Freedom in Design

- Excellent Price Competitiveness

- Complex Shapes Can Be Realized

- Excellent Cold Resistance

Application

Automotive

- Garnish

- Instrument Panel

- Door Trim(Upper)

- Door Trim(Center)

- Arm Rest

- Door Trim(Lower)

- Seat Cover

- Console Box

Technical Data

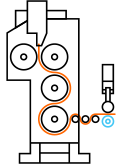

Production Process

Sheet

-

- Calendar

- Produced with raw material processing sheet

-

- Processing

- Raw material processed surface/ back side coating

-

- Embossing

- Foam plywood and embossing

-

- Inspection

- Inspection and packaging (cut or wrapped)

Powder

-

- Formulation & extrusion

- Raw material mixed and toning pelletized

-

- Frozen grinding & sorting

- After cooling off the elastic raw materials, raw materials of large grinding particle size sorted

-

- Post-processing & classification

- The quality of slip between raw materials granted by drying and silica coating

-

- Inspection

- Packaged in line with the customer’s required quantity

Inquiries

- AUTO Interior(IntermLite)

- E-maildkssudkyb@hanwha.com